In modern industrial production, the importance of packaging is self-evident. It is not only the embodiment of the appearance of the product, but also the key to product protection, transportation and sales. However, the traditional manual packaging method has problems such as low efficiency, high labor cost and easy to make mistakes, which can not meet the needs of modern industrial production. At this time, the automatic packing machine came into being, with its efficient, intelligent and stable characteristics, for the packaging work has brought revolutionary changes.

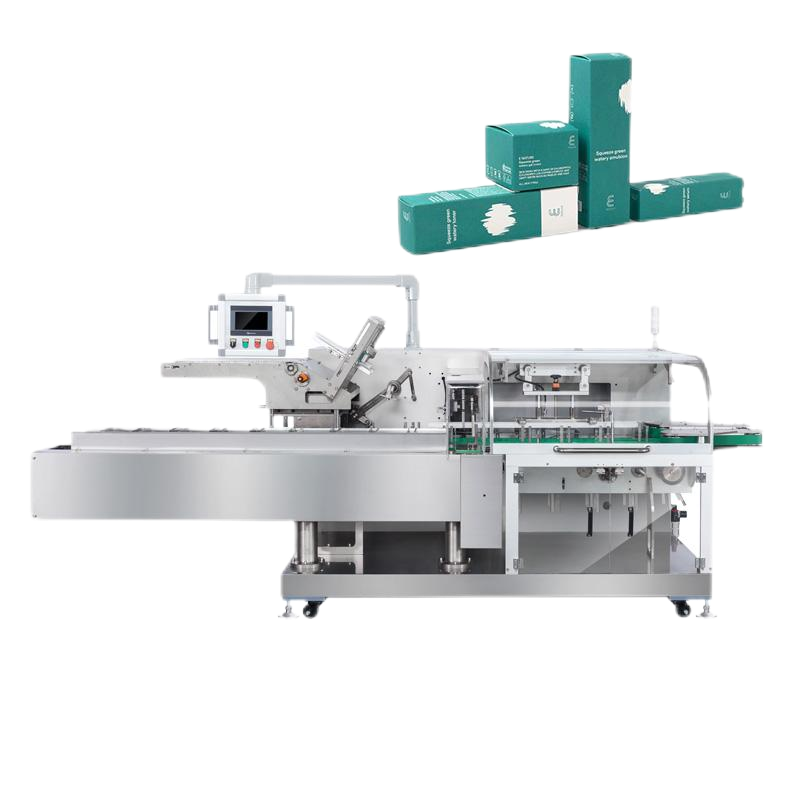

Automatic packing machine is a kind of packaging equipment integrating mechanical, electrical, automatic control and other technologies. It can automatically send the product into the packaging box, and complete the follow-up work such as sealing, labeling, printing, etc. Compared with traditional manual packaging, automatic packing machine has significant advantages:

1,improve production efficiency

The automatic packing machine can complete the packaging work continuously and quickly, which greatly improves the production efficiency. Taking a certain automatic packing machine as an example, it can handle thousands of packaging boxes per hour, which is tens of times or even hundreds of times that of manual packaging. This not only reduces the production cost, but also shortens the product market cycle and enhances the market competitiveness of enterprises.

2,Reduce labor costs

Traditional manual packaging requires a lot of human input, and automatic packaging machines can greatly reduce the need for manpower. With just a few operators monitoring and commissioning the equipment, the entire packaging process can be completed. This not only reduces labor costs, but also reduces the labor intensity of employees and improves job satisfaction.

3,improve the packaging quality

The automatic packing machine uses advanced sensors and control systems to precisely control the position of the product and the sealing quality of the packaging box. This ensures that the appearance and internal products of each packaging box meet a uniform standard, improving the overall quality of the product. At the same time, the automatic packing machine can also avoid packaging damage and pollution caused by human factors.

4,Easy to maintain and upgrade

Automatic packing machines usually have a modular design and are easy to maintain and upgrade. When a device is faulty, the operator can quickly locate and replace the faulty component to ensure the normal running of the device. In addition, with the continuous advancement of technology, automatic packing machines can also be software upgrades and function expansion to adapt to changing market needs.

A wide range of applications

Automatic packing machine is widely used in the packaging production of food, medicine, cosmetics, electronic products and other industries. Whether it is small batch trial production or large-scale production, automatic packing machine can provide stable and reliable packaging solutions. This gives businesses more choice and flexibility.

In summary, the automatic packing machine with its efficient, intelligent, stable characteristics, for the packaging work has brought unprecedented convenience and advantages. It not only improves production efficiency, reduces labor costs, but also improves packaging quality and the market competitiveness of enterprises. In the future, with the continuous progress of technology and the expansion of application fields, automatic packing machine will play a more important role in the packaging industry. Let’s look forward to more surprises and changes brought by the automatic packing machine for packaging work!

发表回复