In modern industrial production, the packaging production line is an important checkpoint before the product leaves the factory, and its efficiency and cost are directly related to the market competitiveness and profit margin of the enterprise. This article will deeply analyze the construction and operation of efficient packaging production lines, and reveal the secrets of improving production efficiency and reducing costs.

The packaging line is designed to improve production efficiency, reduce production costs and ensure product quality. With the progress of science and technology and the change of market demand, the design and implementation of efficient packaging production line has become particularly important. This paper will discuss the design principle, key technology and realization method of high efficiency packaging production line.

Design principles of efficient packaging production line

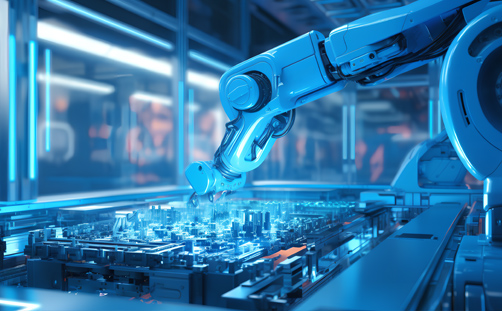

The introduction of advanced automation technology: through the introduction of intelligent equipment such as robots and automatic conveyor belts, the automation and intelligence of the production process are realized, which greatly reduces manual operation and improves production efficiency.

Data-driven production optimization: Use the Internet of Things, big data and other technologies to collect data on the production line in real time, optimize the production process through intelligent analysis, and achieve precise control.

Flexible production line configuration: Modular, reconfigurable production line design, according to product characteristics and market demand, quickly adjust the production line configuration to achieve flexible production.

Accurate material management: Through the optimization of material procurement, inventory management, waste recycling and other links, to achieve accurate material control, reduce waste, reduce costs.

Energy-saving production mode: Adopt energy-saving equipment, optimize production process, reasonable layout and other ways to reduce energy consumption and reduce production costs.

The realization method of efficient packaging production line

Production line layout optimization: According to product characteristics and production process, the production line is rationally arranged to ensure the smooth flow of materials, reduce waste and improve production efficiency.

Equipment selection and configuration: According to the production needs, select the right equipment and configuration to ensure that the performance of the equipment meets the production requirements, while reducing the production cost.

Production process optimization: Through the introduction of automation technology, data-driven production optimization and other methods to optimize the production process, improve production efficiency and reduce production costs.

Employee training and incentive: improve the professional skills and work efficiency of employees through training, and adopt incentive measures to stimulate the enthusiasm and creativity of employees, to provide strong support for the realization of efficient packaging production line.

Case study

Taking the wooden box packaging production line of a large machinery and equipment manufacturer as an example, the production line realizes the automation and intelligence of the production process by introducing automation technology and PLC control system. At the same time, the line also uses a modular design and flexible production line configuration, which can quickly adjust production according to market demand. Through these measures, the production efficiency of the production line has been greatly improved, while reducing production costs.

The design and implementation of high-efficiency packaging production line is an important way for enterprises to improve production efficiency and reduce production costs. Through the introduction of advanced automation technology, data-driven production optimization, flexible production line configuration and other methods, enterprises can build efficient, energy-saving and environmentally friendly packaging production lines, providing strong support for the sustainable development of enterprises. In the future, with the continuous progress of science and technology and the constant changes of the market, the efficient packaging production line will continue to develop in the direction of intelligence, flexibility and green, and create greater value for enterprises.

发表回复